I met Alexandre Zisa a few weeks ago, and I knew right away that he wasn’t the typical aviation

consultant.

When you speak with many consultants, you come away feeling like you know less than you did before. It takes quite a bit of work to understand how they benefit companies and understand the concepts they want to apply. When you speak with Alexandre, however, you feel inspired and empowered. He believes that a good consultant should simplify, rather than complicate concepts for his clients.

If you go to most business consultants asking how to make your product more competitive, most suggest daunting changes like reducing your price and margin, reorganizing the company, or using a different approach to purchasing or sales.

Alexandre’s company, Aevionics, focuses on a concept called “engineered economics” which requires taking financial decisions down a rung on the management ladder—to the people making operational decisions.

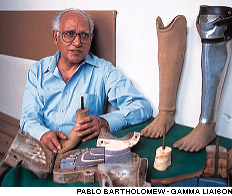

The $1000 car (the Tata Nano) and the $28 Foot (The Jaipur Foot)

are both examples of designing products to meet a cost constraint. For more on these two cases, see

75% of total expenditures are in the hands of operational engineers. These people make millions of the decisions that go into an aircraft, at the level of using a screw versus using a weld versus creating some new type of fastener for a particular purpose. These are very bright people but they typically don’t have access to the information they would need to make the best decision, and answer the question– what is the simplest answer that meets the requirements and offers the lowest cost? Although these principles can bring improvements anywhere in the development cycle, some of the most dramatic results come from beginning – using product development with a target cost as a design parameter. In one celebrated example, building and fitting a functional prosthetic foot for an amputee has traditionally cost tens of thousands of dollars. That cost was brought down to $28 by a team of innovative engineers that used “impossibly” low cost as a primary design consideration of a new prosthesis and fitting process. How can you use this idea in your own business? Address customer objections with product design rather than with pricing. Simply reducing the price can damage the perceived value of your product or cut your margins to dangerous levels which might get your company into financial trouble. A better idea—design a product that meets the cost parameter. Determine the requirements that are absolutely vital at a cost that is acceptable. Using ABCI as an example—we know from consultations with clients that not everyone can afford our consulting services, but many can benefit from great marketing advice at a more modest cost. We now have the Flight Plan to Sales Success book, and the Aviation Marketing Master Class to serve those clients. They get the benefit they need at a price that fits their budget..

Retrieved 11/11/2010 from TED- Ideas Worth Spreading http://www.ted.com/talks/r_a_mashelkar_breakthrough_designs_for_ultra_low_cost_products.html

Even if you’re not in aerospace engineering (Alexandre’s target market) you can use this concept.

Leave A Comment